About CNCTAL

CNCTAL (Dongguan Gemini Hardware Products Co., Ltd.) is a China-based precision CNC machining manufacturer specializing in custom, non-standard metal and plastic parts.

We work with engineers and sourcing teams across Europe and North America, delivering reliable CNC milling and turning solutions — from prototype to small and medium batch production.

Our focus is simple: tight tolerances, stable quality, and clear communication.

Who We Are

CNCTAL is a precision CNC machining manufacturer located in Dongguan, China — one of the world’s most established manufacturing hubs.

We specialize in producing custom, non-standard parts that require consistent quality, tight tolerances, and reliable delivery. Rather than mass production, our strength lies in flexible manufacturing and engineering-driven solutions.

Our team works closely with overseas clients to fully understand technical drawings, functional requirements, and application needs before production begins.

- Custom CNC milling and turning for complex geometries

- Prototype to low & medium volume production

- Aluminum, stainless steel, brass, copper, plastics, and more

- One-stop service including surface finishing and assembly support

What We Do

We provide precision CNC machining services focused on custom parts, tight tolerances, and reliable quality. Our capabilities support the entire manufacturing process — from early-stage prototypes to low and medium volume production.

CNC Machining

CNC milling and CNC turning for complex geometries and high-precision components. Our equipment and experienced machinists allow us to maintain stable quality across repeated production runs.

Materials

We machine a wide range of engineering materials, including aluminum, stainless steel, brass, copper, steel, plastics, and other customer-specified alloys.

Surface Finishing

One-stop surface treatment solutions such as anodizing (Type II & III), electroplating, powder coating, sandblasting, polishing, brushing, and more.

Why Clients Trust CNCTAL

For overseas customers, trust is built through engineering capability, quality control, and consistent execution. CNCTAL focuses on long-term cooperation by delivering predictable results — project after project.

Engineering-Oriented Communication

Our team carefully reviews drawings, tolerances, GD&T, and functional requirements. Potential risks are identified and discussed before machining begins.

Structured Quality Control Process

Quality checks are integrated throughout the production process, including incoming material inspection, in-process checks, and final inspection before shipment.

Reliable Lead Time & Delivery

Clear production planning and internal scheduling allow us to meet agreed lead times and keep customers informed of progress.

Flexible Production Capability

We support prototypes, engineering samples, and low to medium volume production without compromising machining accuracy.

Experience with Global Customers

Extensive cooperation with European and North American clients gives us a strong understanding of international quality standards and expectations.

Continuous Improvement Culture

Feedback from customers and internal reviews drives continuous optimization in machining processes, inspection methods, and workflow efficiency.

Clear Documentation & Traceability

Inspection records, material information, and process documentation are maintained to ensure transparency and traceability for each project.

Risk Control Before Production

We proactively review part geometry, tolerances, and surface requirements to reduce manufacturing risk and avoid costly revisions.

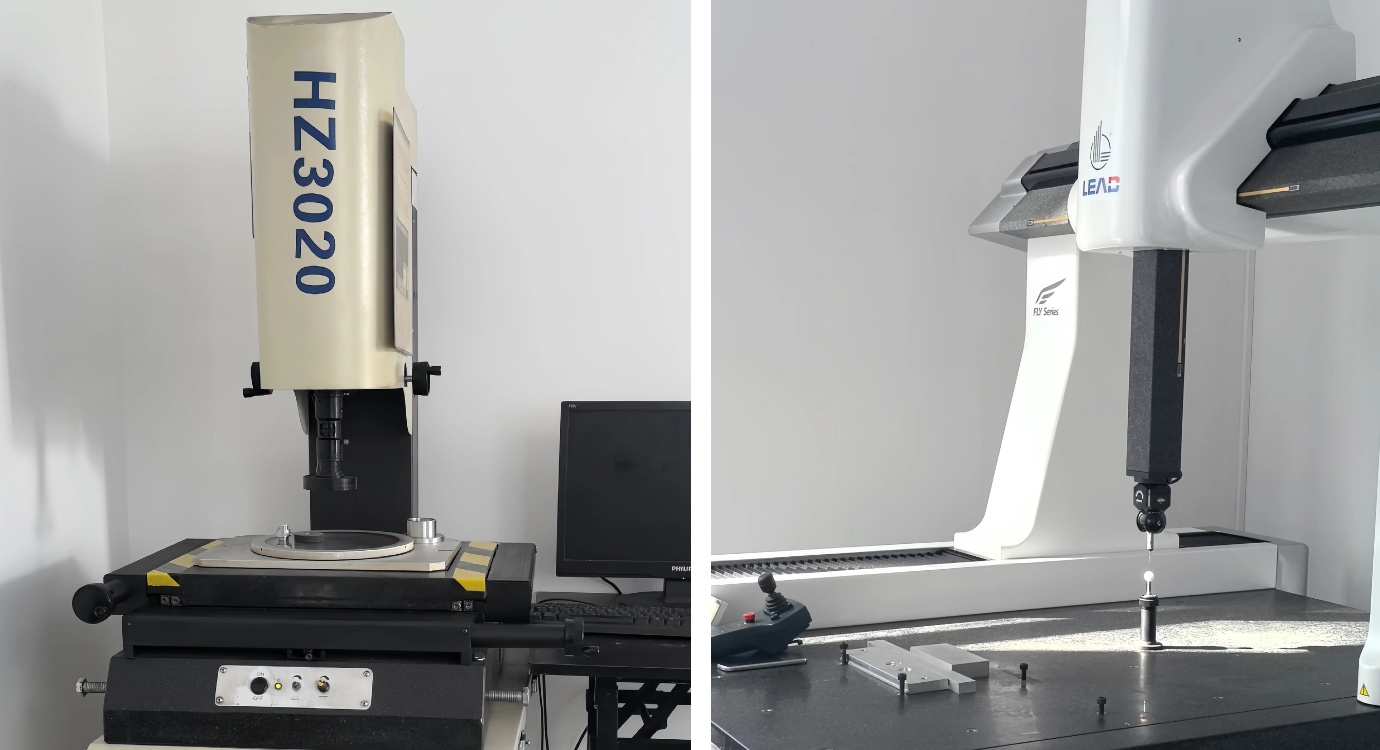

Quality Inspection & Measurement

Precision measurement is a critical part of our quality assurance process. Dimensional accuracy is verified using calibrated inspection tools before parts are approved for shipment.

Depending on part requirements, we perform measurements using calipers, micrometers, height gauges, and coordinate measuring machines (CMM).

This ensures every part meets drawing specifications and functional expectations.

Factory & Team

Our manufacturing facility is equipped with modern CNC machines and organized production lines designed for precision machining.

From CNC milling and turning to secondary processes and surface finishing, our factory supports flexible production while maintaining stable quality standards.

Standardized workflows and experienced operators allow us to handle complex parts efficiently and reliably.

Machining Team

Experienced CNC OperatorsSkilled machinists responsible for setup, programming, and machining accuracy on CNC milling and turning equipment.

Quality Team

Inspection & MeasurementDedicated inspectors performing dimensional checks using calipers, gauges, and CMM equipment.

Engineering Support

Drawing Review & Process PlanningEngineers supporting drawing review, manufacturability analysis, and production planning.

Project Coordination

Overseas Customer SupportProject coordinators ensuring clear communication, progress updates, and on-time delivery.

Let’s Build Precision Parts Together

Looking for a reliable CNC machining partner for your next project? Send us your drawings, specifications, or questions — our team will review your requirements and get back to you promptly.

Email: gemini@cnctal.com