Precision CNC Machining

Professional CNC Milling, CNC Turning, and 5-Axis Machining services for high-precision custom parts — from rapid prototyping to production.

CNC Machining Services

We provide a full range of CNC machining services to support complex parts, tight tolerances, and demanding applications. Our capabilities cover CNC milling, CNC turning, and advanced 5-axis machining for both prototypes and production runs.

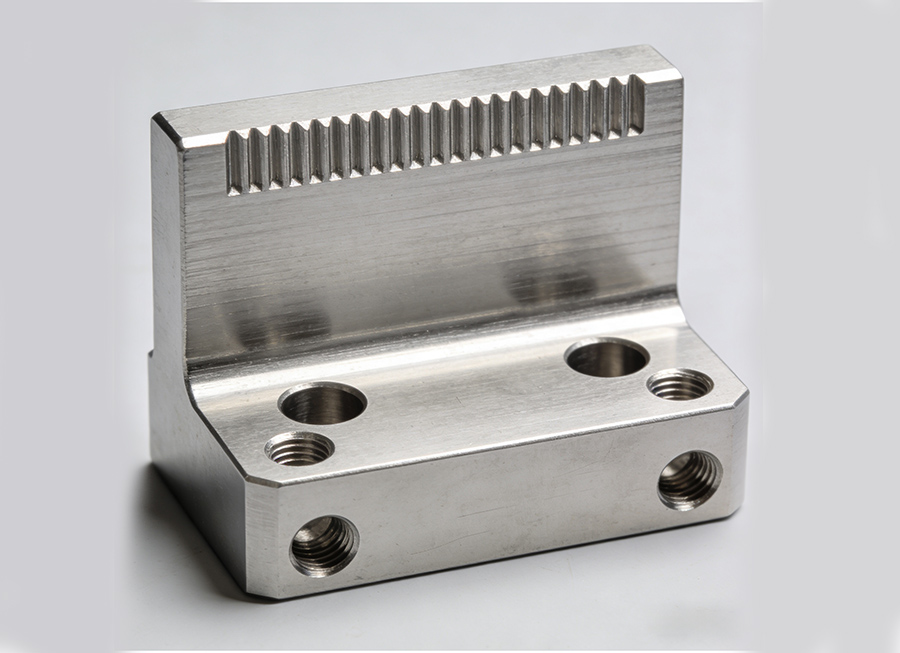

CNC Milling

CNC milling is ideal for producing complex shapes, pockets, slots, and precision surfaces. Our multi-axis milling centers deliver high accuracy and repeatability for custom components.

- 3-axis & multi-axis milling

- High precision flatness and surface quality

- Suitable for aluminum, steel, plastics, and more

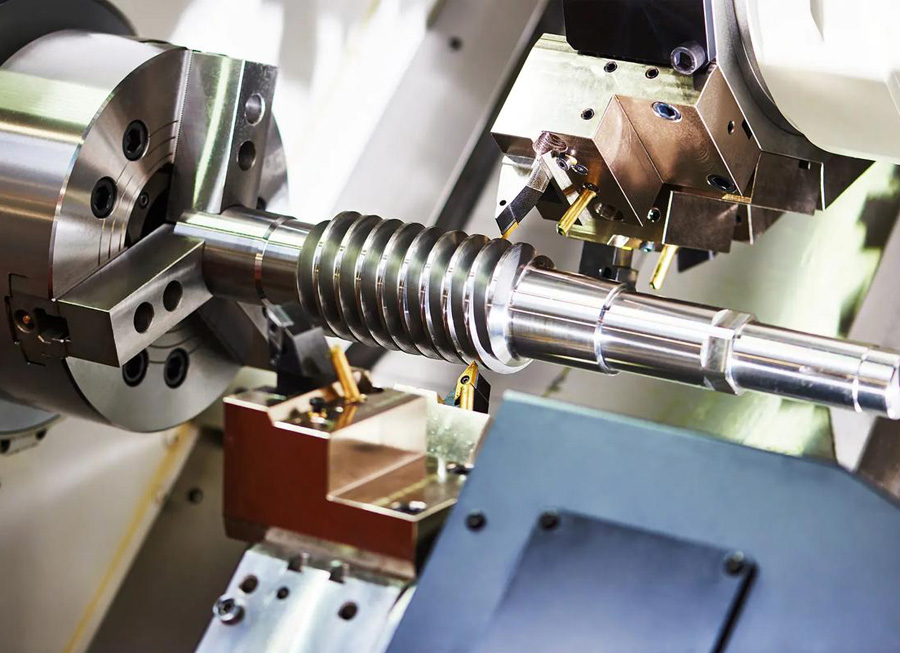

CNC Turning

CNC turning is used for round or cylindrical parts requiring tight concentricity and smooth finishes. Our turning centers support both simple and complex turned components.

- High-speed CNC lathes

- Excellent roundness and concentricity

- Ideal for shafts, bushings, and fittings

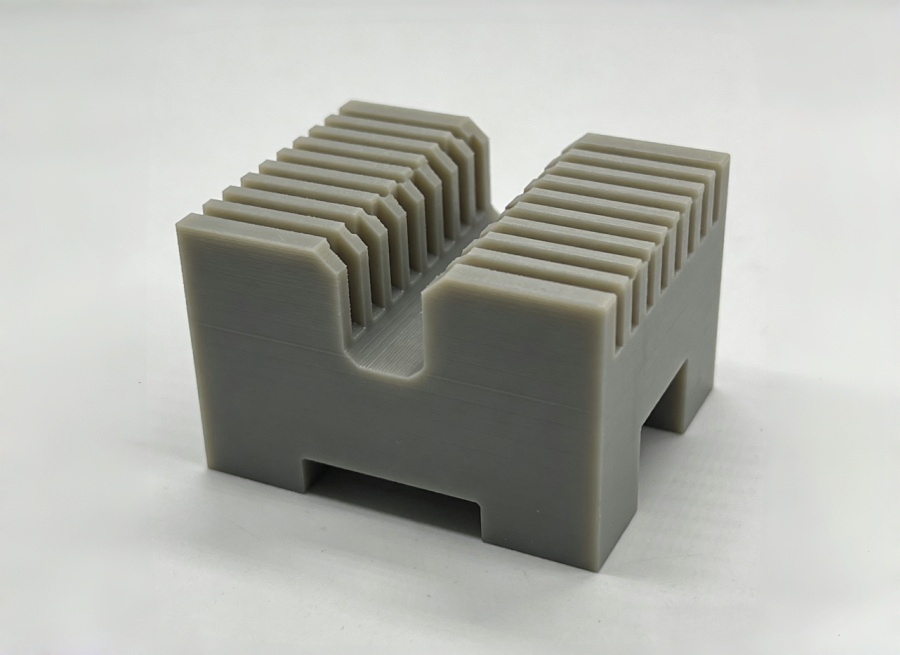

5-Axis CNC Machining

5-axis CNC machining enables complex geometries, undercuts, and multi-sided machining in a single setup, reducing errors and improving overall part quality.

- Complex geometry & tight tolerance parts

- Reduced setups and higher accuracy

- Perfect for aerospace and high-end applications

Surface Grinding Service

Surface grinding provides ultra-flat surfaces and precise dimensional control for components requiring tight tolerances and superior surface finishes.

- High flatness & parallelism

- Excellent surface finish quality

- Ideal for precision and functional parts

Why Choose Our CNC Machining Services

Choosing the right CNC machining partner is critical to the success of your project. At CNCTAL, we combine advanced machining capabilities with strict quality control and responsive engineering support to deliver reliable, high-precision parts for global customers.

High Precision Machining

Advanced CNC milling, turning, and 5-axis equipment enable us to achieve tight tolerances up to ±0.01 mm, ensuring dimensional accuracy and consistency.

Experienced Engineering Team

Our engineers review every drawing and provide manufacturability feedback to help optimize designs, reduce cost, and avoid production risks.

Prototype to Production

From rapid prototypes to small and medium batch production, we support flexible quantities without compromising quality.

Wide Material & Process Support

We machine aluminum, stainless steel, brass, copper, plastics, and more, with a complete range of surface finishing options available.

Strict Quality Control

Each part is inspected according to drawings using precision measuring equipment to meet international quality and inspection standards.

Fast Response & Reliable Delivery

Efficient internal workflow allows us to provide quick quotations, stable lead times, and dependable delivery for overseas customers.

CNC Milling Parts Tolerances & Standards (ISO 2768)

Our CNC milling parts are manufactured according to ISO 2768 general tolerances unless otherwise specified on the engineering drawing. This standard is widely applied to custom CNC milled components and defines permissible dimensional variations when individual tolerances are not indicated.

| Feature | Standard Tolerance |

|---|---|

| Linear dimensions | ±0.1 mm |

| Hole diameter | ±0.05 mm |

| Shaft diameter | ±0.05 mm |

| Flatness | ISO 2768-m |

| Parallelism | ISO 2768-m |

| Perpendicularity | ISO 2768-m |

| Angular dimensions | ISO 2768-m |

Tighter tolerances can be achieved for critical functional features depending on part geometry, material, and machining method. If no tolerance is specified on the drawing, ISO 2768-m will be applied as the default standard. Please clearly indicate any special tolerance requirements in your technical documentation.

CNC Milling Materials Available

Aluminum CNC Milling

Aluminum offers excellent machinability, lightweight properties, and a high strength-to-weight ratio.

Widely used in aerospace, automotive, electronics, and industrial components.

View More >

Stainless Steel CNC Milling

Stainless steel provides excellent corrosion resistance and mechanical strength.

Common grades include 303, 304, and 316 for precision machined parts.

View More >

Carbon Steel CNC Milling

Carbon steel is known for its strength, durability, and cost efficiency.

Suitable for structural and mechanical components.

View More >

Brass & Copper CNC Milling

Brass and copper offer excellent electrical conductivity and corrosion resistance.

Ideal for connectors, fittings, and electrical components.

View More >

Titanium Alloys CNC Milling

Titanium alloys combine high strength, low weight, and excellent corrosion resistance.

Commonly used in aerospace, medical, and high-performance applications.

View More >

Nylon (Polyamide / PA)

Nylon offers good toughness, wear resistance, and dimensional stability.

Suitable for gears, bushings, and functional plastic parts.

View More >

PEEK (Polyether Ether Ketone)

PEEK is a high-performance engineering plastic with excellent heat and chemical resistance.

Ideal for aerospace, medical, and precision industrial applications.

View More >Surface Finishing Capabilities

We provide a comprehensive range of surface finishing services to improve corrosion resistance, wear performance, and visual appearance of CNC machined parts. Suitable for both functional and cosmetic requirements.

Deburring & Edge Rounding

Removes sharp edges and burrs from parts to improve safety, performance, and assembly compatibility.

Polishing

Produces smooth or mirror-like surfaces for decorative parts and reduced surface friction.

Sandblasting

Creates a uniform matte surface and removes machining marks, commonly used as a pre-treatment before anodizing or coating.

Anodizing

Enhances corrosion resistance and appearance of aluminum parts, available in clear and multiple color options.

Electroplating

Applies zinc, nickel, or other metal coatings to improve corrosion resistance and surface durability of steel components.

Conversion Coating

Provides a protective oxide layer for aluminum, enhancing corrosion resistance and paint adhesion.

Spray Coating

Applies a uniform coating to improve wear and corrosion resistance, suitable for functional and decorative finishes.

Laser Marking

Uses laser technology to engrave precise markings, serial numbers, and logos on metal or plastic surfaces.

Process Workflow

Start Your CNC Milling Project

Upload your drawings or CAD files to receive a fast and accurate quote. Our engineering team supports prototype to low- and medium-volume CNC milling with consistent quality and reliable lead times.