CNC Milling Services

Precision CNC milling services for complex prismatic parts, housings, brackets, and custom components. From prototyping to low- and medium-volume production with tight tolerances and reliable quality.

CNC Milling vs CNC Mill-Turning vs 5-Axis CNC Machining

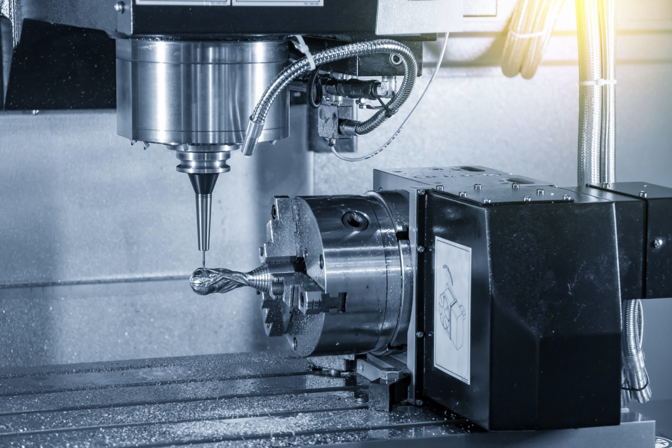

CNC Milling Service Overview

Our CNC milling services are tailored for high-precision custom parts, delivering consistent dimensional accuracy and reliable repeatability across prototypes and production runs.

CNC milling is ideal for prismatic parts, housings, brackets, and mechanical components with complex geometries. Our precision milling ensures tight tolerances and multi-surface machining capabilities.

From rapid prototyping to low- and medium-volume production, we provide consistent quality, fast turnaround, and reliable lead times for engineering-driven projects.

Typical CNC Milling Applications

- Mechanical housings and enclosures

- Structural brackets and mounting parts

- Precision plates and base components

- Custom fixtures and tooling

- Assembly-critical machined parts

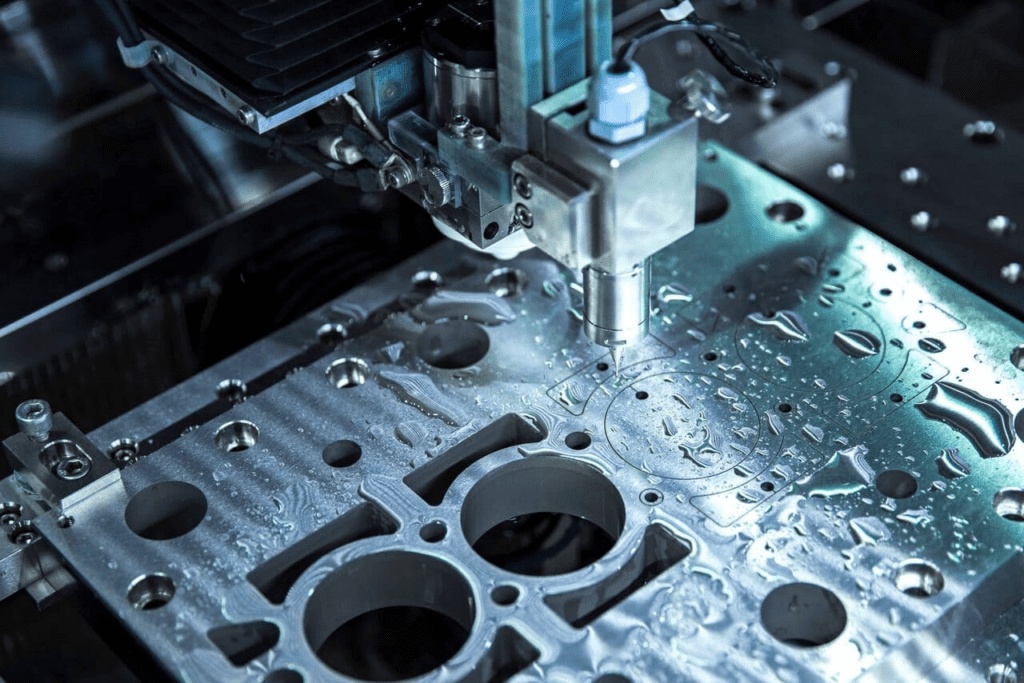

3-Axis & 4-Axis CNC Milling

Our CNC milling operations support both 3-axis and 4-axis machining, allowing us to produce parts with complex geometries and precise features in a controlled and repeatable process.

- Multi-face machining with improved accuracy

- Reduced setup changes for better consistency

- Suitable for prismatic and complex milled components

Tight Tolerance & Complex Geometry

Our CNC milling process is designed to achieve tight dimensional control for parts with complex pockets, contours, and profiles.

- Tolerance control up to ±0.01 mm

- Machining of deep pockets and fine features

- Stable repeatability across production runs

Prototype to Low-to-Mid Volume Production

We support CNC milling projects from early-stage prototypes to stable low-to-mid volume production, ensuring consistent quality throughout the product lifecycle.

- Engineering support and DFM feedback

- Process optimization for repeat production

- Reliable lead time for export projects

Our CNC milling capabilities are supported by standardized process control and inspection procedures to ensure dimensional accuracy and production stability for every project.

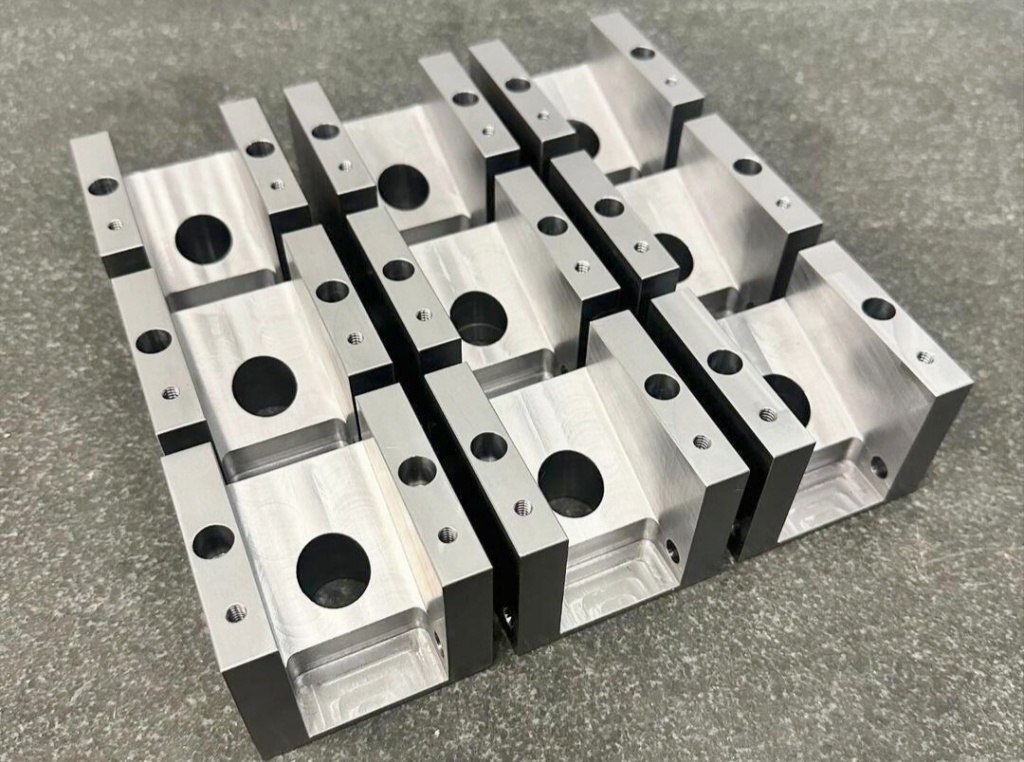

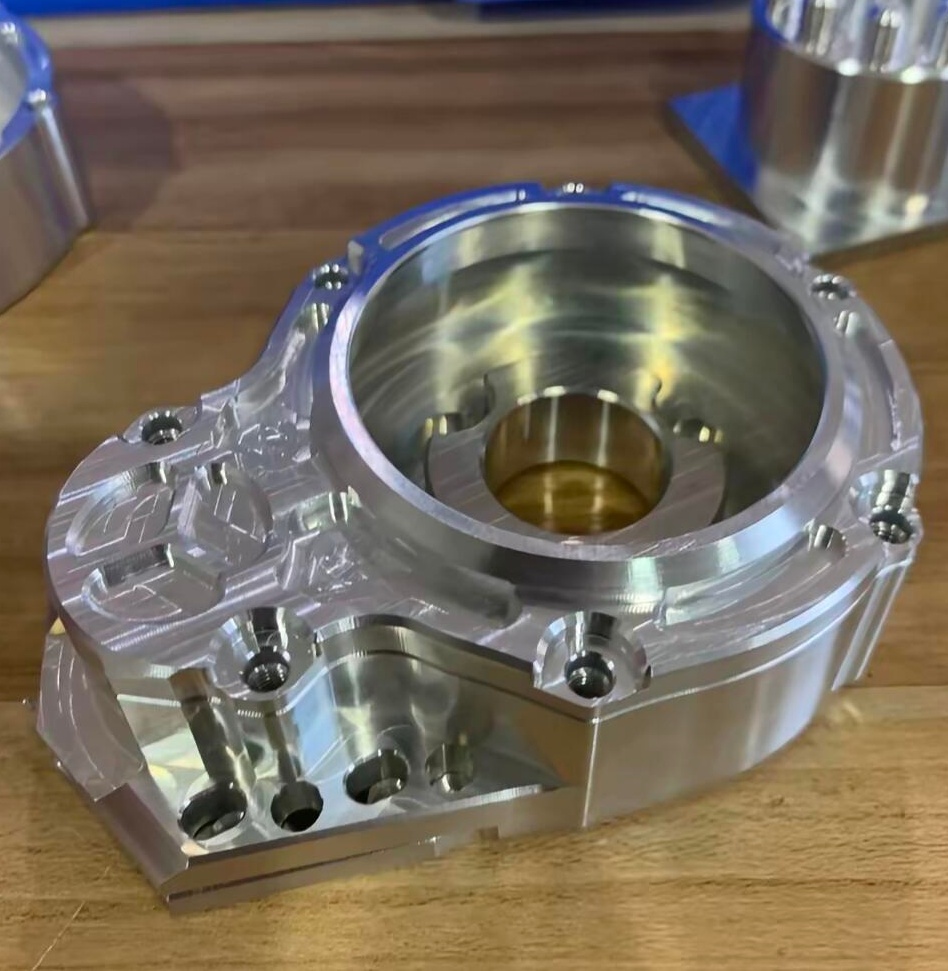

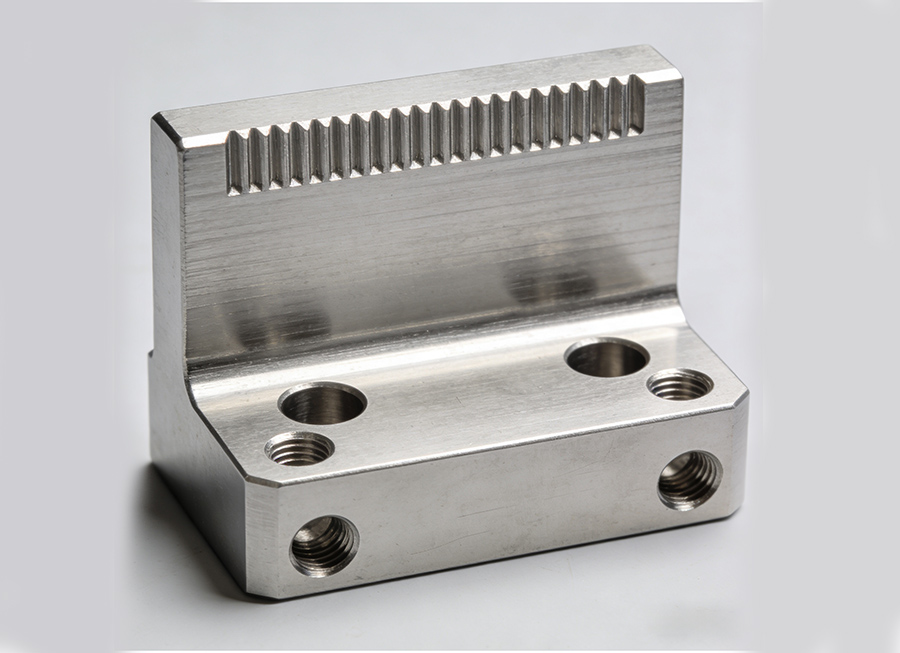

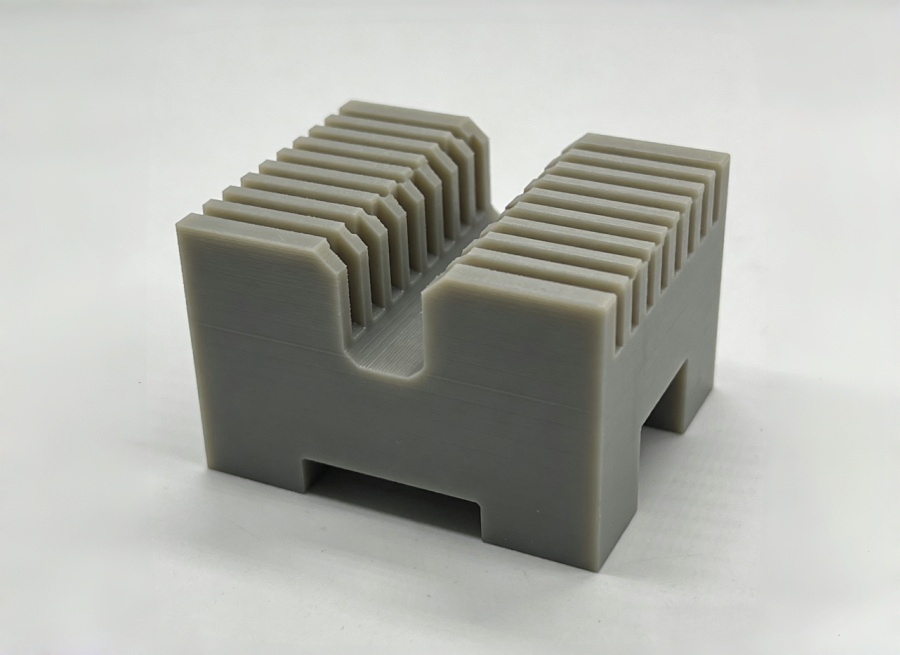

CNC Milling Product Examples

Precision CNC milling parts produced for industrial, automotive, medical, and custom applications. All parts are manufactured to tight tolerances and customer specifications.

Quality Control in CNC Milling

Quality control is an integral part of our CNC milling process. From raw material inspection to final dimensional verification, each step is managed to ensure accuracy, repeatability, and reliable performance for precision machined parts.

Incoming Material Inspection

Raw materials are inspected upon arrival to verify specifications, material grade, and surface condition before entering the CNC milling process.

In-Process Dimensional Control

Key dimensions are monitored during machining to minimize variation and ensure stable tolerance control throughout production.

Final Inspection Before Shipment

Finished parts undergo final dimensional and visual inspection to confirm conformity with drawings and customer requirements.

Inspection Equipment & Reporting

- Coordinate Measuring Machine (CMM)

- Calipers, Micrometers, and Height Gauges

- Dimensional inspection reports available upon request

- First Article Inspection (FAI) support

- Inspection records maintained for traceability

CNC Milling Parts Tolerances & Standards (ISO 2768)

Our CNC milling parts are manufactured according to ISO 2768 general tolerances unless otherwise specified on the engineering drawing. This standard is widely applied to custom CNC milled components and defines permissible dimensional variations when individual tolerances are not indicated.

| Feature | Standard Tolerance |

|---|---|

| Linear dimensions | ±0.1 mm |

| Hole diameter | ±0.05 mm |

| Shaft diameter | ±0.05 mm |

| Flatness | ISO 2768-m |

| Parallelism | ISO 2768-m |

| Perpendicularity | ISO 2768-m |

| Angular dimensions | ISO 2768-m |

Tighter tolerances can be achieved for critical functional features depending on part geometry, material, and machining method. If no tolerance is specified on the drawing, ISO 2768-m will be applied as the default standard. Please clearly indicate any special tolerance requirements in your technical documentation.

CNC Milling Materials Available

Aluminum CNC Milling

Aluminum offers excellent machinability, lightweight properties, and a high strength-to-weight ratio.

Widely used in aerospace, automotive, electronics, and industrial components.

View More >

Stainless Steel CNC Milling

Stainless steel provides excellent corrosion resistance and mechanical strength.

Common grades include 303, 304, and 316 for precision machined parts.

View More >

Carbon Steel CNC Milling

Carbon steel is known for its strength, durability, and cost efficiency.

Suitable for structural and mechanical components.

View More >

Brass & Copper CNC Milling

Brass and copper offer excellent electrical conductivity and corrosion resistance.

Ideal for connectors, fittings, and electrical components.

View More >

Titanium Alloys CNC Milling

Titanium alloys combine high strength, low weight, and excellent corrosion resistance.

Commonly used in aerospace, medical, and high-performance applications.

View More >

Nylon (Polyamide / PA)

Nylon offers good toughness, wear resistance, and dimensional stability.

Suitable for gears, bushings, and functional plastic parts.

View More >

PEEK (Polyether Ether Ketone)

PEEK is a high-performance engineering plastic with excellent heat and chemical resistance.

Ideal for aerospace, medical, and precision industrial applications.

View More >Typical CNC Milling Applications

Automotive Manufacturing

Precision milled components for engines, transmissions, chassis systems, and automotive tooling.

Aerospace

High-tolerance CNC milled parts for aircraft structures, brackets, housings, and engine components.

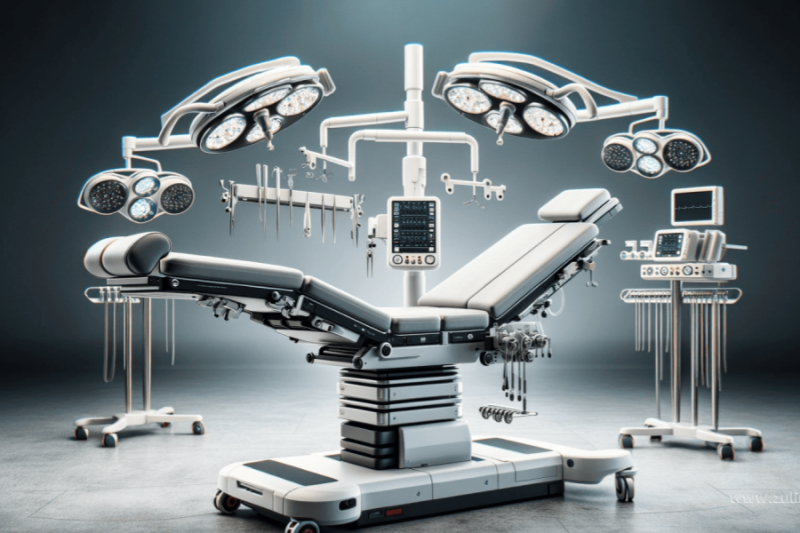

Medical Devices

CNC milling for surgical instruments, diagnostic equipment, and precision medical components.

Industrial Robotics

Milled robot arms, end effectors, fixtures, and high-precision mechanical structures.

Electronics Manufacturing

CNC milled enclosures, heat sinks, connectors, and precision electronic housings.

Defense & Military

High-strength CNC milled parts for defense equipment, weapon systems, and structural components.

Energy & Power Generation

Precision CNC milling for turbines, power systems, and renewable energy components.

Consumer Products

CNC milled parts for consumer electronics, appliances, and high-end product housings.

Start Your CNC Milling Project

Upload your drawings or CAD files to receive a fast and accurate quote. Our engineering team supports prototype to low- and medium-volume CNC milling with consistent quality and reliable lead times.