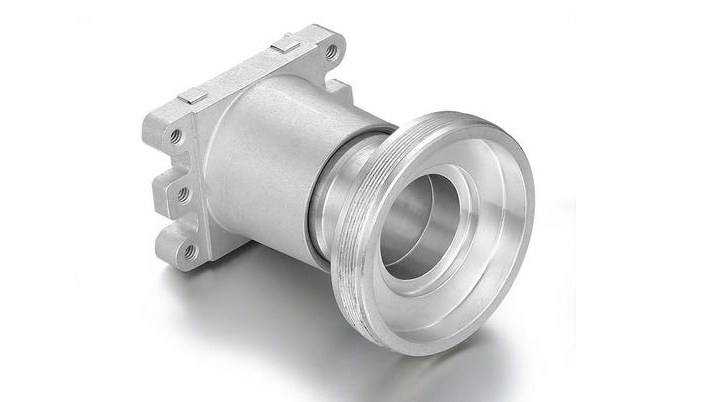

Stainless Steel for Durable CNC Machined Parts

Stainless steel is valued for its excellent mechanical strength, corrosion resistance, and long-term durability, making it a preferred material for demanding industrial environments.

Compared to aluminum, stainless steel requires more advanced CNC process control due to higher cutting forces and heat generation. At CNCTAL, optimized tooling strategies and cutting parameters ensure consistent precision and repeatability.

- High strength and load-bearing capability

- Excellent corrosion and wear resistance

- Stable performance in harsh environments

- Controlled heat management for dimensional accuracy

Common Stainless Steel Grades We Machine

303 304 316 17-4 PH 420

Aluminum vs Stainless Steel in CNC Machining

Aluminum and stainless steel are two of the most commonly used CNC machining materials. Each offers distinct advantages depending on precision requirements, strength, corrosion resistance, and cost.

| Comparison Factor | Aluminum Alloys | Stainless Steel |

|---|---|---|

| CNC Machinability | ★★★★★ Excellent | ★★★☆☆ Moderate |

| Dimensional Stability | Very stable, low deformation risk | Stable, requires heat control |

| Achievable Tolerances | ±0.01 mm easily achievable | ±0.01–0.02 mm with controlled process |

| Strength & Hardness | Moderate (high strength-to-weight ratio) | High mechanical strength |

| Corrosion Resistance | Good (excellent after anodizing) | Excellent (natural corrosion resistance) |

| Surface Finish Quality | Excellent, cosmetic-grade finishes | Good, polishing often required |

| Production Efficiency | High speed, low tool wear | Slower cutting, higher tool wear |

| Overall CNC Reliability | ★★★★★ Very High | ★★★★☆ High |

Material Selection Recommendation

Choose aluminum alloys for lightweight, high-precision parts

where efficiency, surface quality, and cost control are critical.

Choose stainless steel for applications requiring higher

strength, corrosion resistance, and durability in harsh environments,

accepting longer machining times and higher tooling demands.

CNC Machining Material Categories

We machine a wide range of metals and engineering plastics. Each material category is selected and processed based on machinability, dimensional stability, and long-term reliability in real production environments.

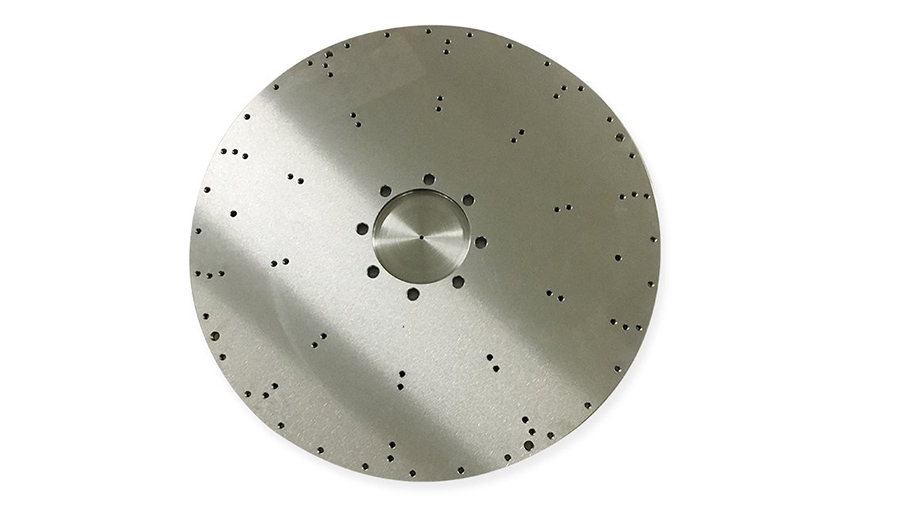

Aluminum Alloys

Lightweight, stable, and highly machinable. Aluminum is ideal for precision parts requiring tight tolerances and excellent surface finishes.

- Excellent machinability

- Low deformation risk

- Ideal for anodizing

Stainless Steel

Known for corrosion resistance and mechanical strength, stainless steel is widely used in demanding industrial and medical applications.

- Excellent corrosion resistance

- High structural strength

- Consistent dimensional stability

Carbon & Alloy Steel

A balanced choice offering strength, durability, and cost efficiency, especially suitable for mechanical and load-bearing components.

- Good strength-to-cost ratio

- Suitable for heat treatment

- Stable for batch production

Titanium Alloys

Titanium offers exceptional strength-to-weight ratio and corrosion resistance, making it ideal for aerospace and medical components.

- High strength-to-weight ratio

- Excellent corrosion resistance

- Advanced CNC process control required

Copper & Brass

Ideal for electrical and thermal applications where conductivity and precision are critical.

- Excellent electrical conductivity

- Good surface finish

- Precision control required

Engineering Plastics

Engineering plastics provide chemical resistance, low weight, and dimensional stability for non-metal applications.

- Low weight & chemical resistance

- Stable for precision machining

- Ideal for insulation components

Material Selection Guide

Choosing the right material is critical to performance, cost, and lead time. This guide helps engineers and buyers quickly compare common CNC machining materials based on strength, weight, corrosion resistance, machinability, and cost.

| Material | Strength | Weight | Corrosion Resistance | Machinability | Cost Level | Best For |

|---|---|---|---|---|---|---|

| Aluminum | Medium | Very Light | Good | Excellent | Low – Medium | Lightweight parts, housings, prototypes |

| Stainless Steel | High | Heavy | Excellent | Medium | High | Medical, food-grade, outdoor components |

| Carbon Steel | Medium – High | Heavy | Poor | Good | Low | Structural parts, brackets, shafts |

| Alloy Steel | Very High | Heavy | Poor – Medium | Medium | Medium | Gears, tooling, load-bearing components |

| Brass | Medium | Medium | Good | Excellent | Medium | Fittings, valves, decorative parts |

| Copper | Low – Medium | Heavy | Excellent | Poor | High | Electrical, thermal applications |

| Plastic (POM / Nylon) | Low | Very Light | Excellent | Excellent | Low | Insulators, low-load functional parts |

* This material guide is for reference only. Final material selection should consider part geometry, tolerance, surface finish, operating environment, and production volume. Our engineers are happy to recommend the most suitable material for your project.

Not Sure Which Material to Choose?

Our engineers can help you select the optimal material for your CNC machined parts based on strength, cost, weight, and application environment. Upload your drawings or contact us for a professional recommendation.

Contact Us / Upload Drawing