Surface Finishing Services

Professional surface finishing services to improve appearance, corrosion resistance, wear performance, and functional properties of CNC machined parts. Suitable for both functional and cosmetic requirements.

Why Choose CNCTAL for Surface Finishing

CNCTAL delivers reliable, high-quality surface finishing solutions designed to enhance performance, appearance, and durability of precision CNC parts.

30+ Finishing Options

From anodizing and powder coating to polishing and plating, we offer a wide range of finishing solutions for diverse applications.

Strict Quality Control

Coating thickness, adhesion, corrosion resistance and visual inspection are strictly controlled to meet your specifications.

Precision & Consistency

Advanced equipment and experienced technicians ensure consistent, repeatable surface quality across every production batch.

Custom Finishing Solutions

We help you select the most suitable surface finish based on material, function, industry requirements, and end-use environment.

Surface Finishing Capabilities

We provide a comprehensive range of surface finishing services to improve corrosion resistance, wear performance, and visual appearance of CNC machined parts. Suitable for both functional and cosmetic requirements.

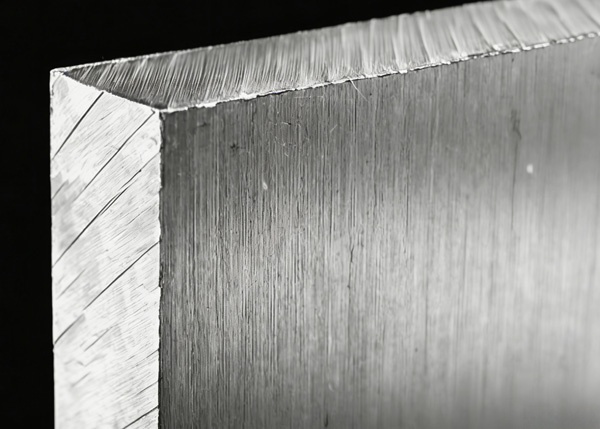

Deburring & Edge Rounding

Removes sharp edges and burrs from parts to improve safety, performance, and assembly compatibility.

Polishing

Produces smooth or mirror-like surfaces for decorative parts and reduced surface friction.

Sandblasting

Creates a uniform matte surface and removes machining marks, commonly used as a pre-treatment before anodizing or coating.

Anodizing

Enhances corrosion resistance and appearance of aluminum parts, available in clear and multiple color options.

Electroplating

Applies zinc, nickel, or other metal coatings to improve corrosion resistance and surface durability of steel components.

Conversion Coating

Provides a protective oxide layer for aluminum, enhancing corrosion resistance and paint adhesion.

Spray Coating

Applies a uniform coating to improve wear and corrosion resistance, suitable for functional and decorative finishes.

Laser Marking

Uses laser technology to engrave precise markings, serial numbers, and logos on metal or plastic surfaces.

Surface Finishing Service Overview

Surface finishing plays a critical role in enhancing part performance, appearance, and durability. Our surface finishing services are designed to meet both functional and aesthetic requirements for CNC machined components.

By integrating surface treatment directly into our production workflow, we ensure consistent quality, controlled lead times, and reliable results for both prototype and production parts.

- Improve corrosion resistance and surface hardness

- Enhance visual appearance and surface uniformity

- Support functional requirements such as wear resistance and conductivity

- One-stop solution aligned with CNC machining tolerances

Surface Finishing Types

CNCTAL provides a comprehensive range of surface finishing services to enhance the performance, durability, and appearance of CNC machined parts.

Anodizing

Improves corrosion resistance and surface hardness while offering various color options for aluminum parts.

Powder Coating

Provides a durable, uniform, and decorative coating with excellent resistance to wear and environmental exposure.

Sandblasting

Creates a uniform matte texture while removing minor surface imperfections and machining marks.

Polishing

Produces a smooth or mirror-like surface finish for high-end aesthetic and precision applications.

Quality Control & Inspection

At CNCTAL, every surface finishing process is strictly inspected to ensure compliance with technical requirements, industry standards, and customer specifications.

Coating Thickness

Measured to ensure uniform coverage without affecting part dimensions or tolerances.

Surface Roughness

Ra values and visual consistency are inspected to meet functional and aesthetic requirements.

Adhesion & Hardness

Tested to verify coating durability and resistance to wear and mechanical stress.

Corrosion Resistance

Salt spray and environmental testing are performed when required to validate long-term performance.

Standards & Compliance

Our surface finishing processes follow internationally recognized quality standards to ensure reliability and repeatability.

- ISO 9001 Quality Management System

- ISO 13485 (Medical Applications)

- RoHS & REACH Compliance

- Customer-Specific Inspection Requirements

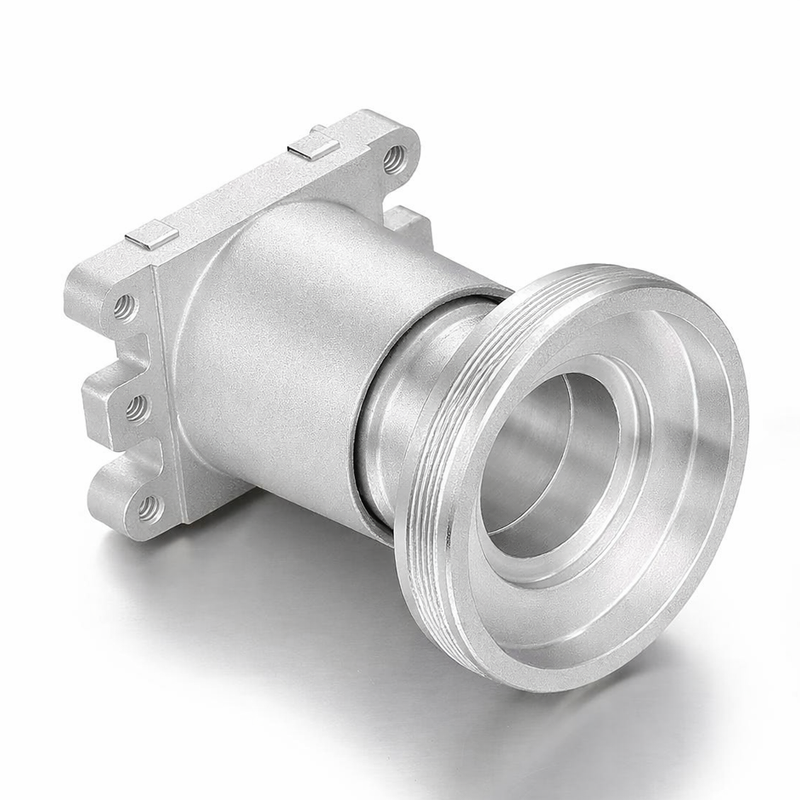

Surface Finishing Examples

Explore real CNC machined parts with different surface finishing options. These examples demonstrate how surface treatments enhance appearance, performance, and durability.

Anodized Aluminum Parts

- Material: Aluminum 6061

- Finish: Anodizing (Black)

- Application: Electronics enclosures, brackets

Polished Stainless Steel Parts

- Material: Stainless Steel 304

- Finish: Polishing

- Application: Medical & decorative components

Powder Coated CNC Parts

- Material: Steel

- Finish: Mirror polishing

- Application: Kitchen and bathroom and electronic control panels

Start Your CNC Milling Project

Upload your drawings or CAD files to receive a fast and accurate quote. Our engineering team supports prototype to low- and medium-volume CNC milling with consistent quality and reliable lead times.