What is CNC Machining?

CNC (Computer Numerical Control) machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. It can control a wide range of complex machines, including lathes, mills, grinders, and routers.

Precision CNC machining allows engineers to produce highly accurate and repeatable parts, suitable for prototypes, small-batch production, and complex geometries.

CNC Machining Processes

CNC Milling: Removing material from a workpiece using rotary cutters. Ideal for complex 3D shapes.

CNC Turning: Rotating the workpiece against cutting tools to create cylindrical shapes.

Drilling & Tapping: Accurate holes and threads for assembly.

Wire EDM: Precision cutting of hard metals with minimal heat impact.

Materials Commonly Used

CNC machining supports a wide variety of materials: metals such as aluminum, stainless steel, brass, copper, titanium, and engineering plastics like ABS, Nylon, PEEK, Delrin. Custom alloys can also be machined according to client specifications.

Surface Finishing

After machining, parts often require surface finishing to improve aesthetics, wear resistance, or corrosion protection. Common processes include:

- Anodizing (Type II & III)

- Electroplating (Zinc, Nickel, Chrome)

- Powder Coating

- Polishing & Brushing

Quality Control

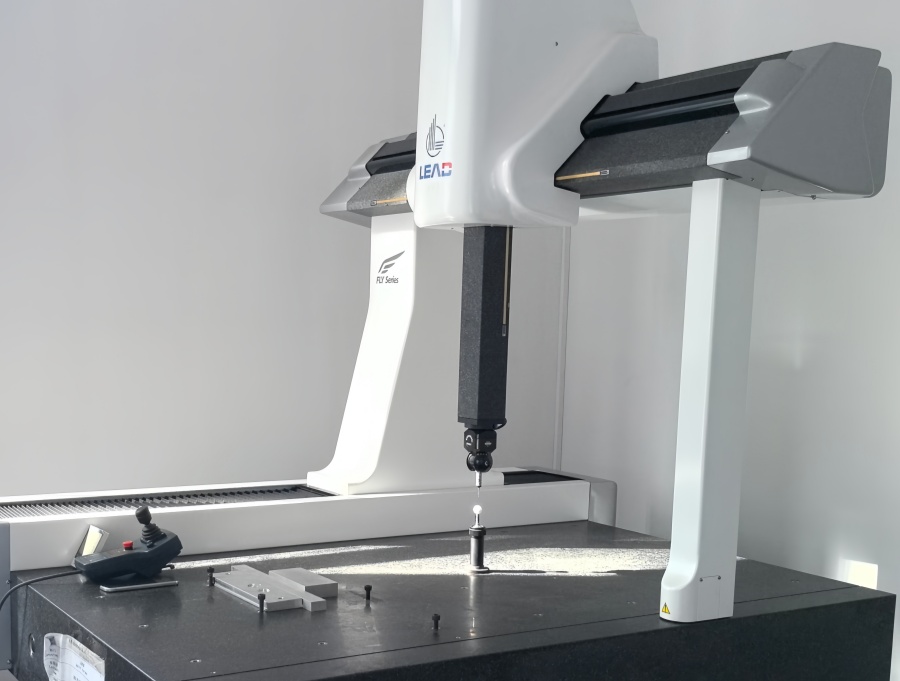

Quality control is integrated into every step of our workflow. Inspections are performed using calipers, micrometers, height gauges, and coordinate measuring machines (CMM).

This ensures each component meets the required tolerances, dimensions, and functional standards.

Why Precision Matters

High-precision CNC machining ensures parts fit perfectly in assembly, perform consistently, and reduce waste. Small deviations can affect complex mechanical systems, especially in aerospace, medical devices, and electronics.

Conclusion

Precision CNC machining combines advanced machinery, skilled operators, and strict quality control to produce parts that meet exact specifications. At CNCTAL, we specialize in custom CNC solutions for overseas customers, delivering prototypes, low-volume production, and finished components with reliable quality and service.